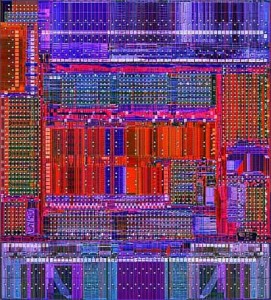

Wire bonding, a critical step in semiconductors

Wire bonding is the method that provides electrical connection between semiconductors and circuit boards using super fine aluminum, copper, or gold material. More than 80 percent of semiconductors are still using the decade-old wire-bonding technology. This method is generally considered the most cost effective and flexible interconnect technology for wire bonding in semiconductors. Main materials used for wire bonding include aluminum, copper and gold. There are three common methods of bonding; ball bonding, wedge bonding, and compliant bonding. Ball bonding is limited to copper and gold while wedge bonding is used with gold or aluminum. Complaint bonding is limited to gold.

Wire bonding is the method that provides electrical connection between semiconductors and circuit boards using super fine aluminum, copper, or gold material. More than 80 percent of semiconductors are still using the decade-old wire-bonding technology. This method is generally considered the most cost effective and flexible interconnect technology for wire bonding in semiconductors. Main materials used for wire bonding include aluminum, copper and gold. There are three common methods of bonding; ball bonding, wedge bonding, and compliant bonding. Ball bonding is limited to copper and gold while wedge bonding is used with gold or aluminum. Complaint bonding is limited to gold.

But a new line of technologies are changing the traditional gold wire standard in the semiconductor industry. Singapore based RED Micro Wire (RMW) announced in March 2012 that it came up with a process that include copper wire in glass insulation that offer cost savings and other benefits. Another company, Semikron has developed a new packaging technique removing the need for bond wires and using a flexible foil and sintered connections. New technology results in higher current carrying capacity, load cycle capability, optimum thermal and electrical chip connectivity, and remove the need for wire bonding and soldered base plate.