Vacuum Deposition and the Relationship Between Household Items and Coating

Look around your house, many of your items have undergone vacuum deposition.

As an outsider looking in, you may not be familiar with the term ‘thin film vacuum coating’. However, did you know that many of your household items are created through vacuum coating?

As an outsider looking in, you may not be familiar with the term ‘thin film vacuum coating’. However, did you know that many of your household items are created through vacuum coating?

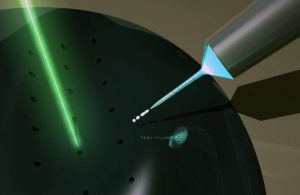

To break it down, vacuum coating is done through the use of vacuum deposition systems. Situated within a vacuum environment, the process of vacuum coating utilizes less-than-ambient pressure and plasma to produce a substrate, which is essentially the end product. There are numerous methods in which materials can be deposited. Some of them include: chemical vapor deposition, physical deposition, and so on. The type of material that is chosen for the process decides which method is to be used.

Packaging Products

One of the more common household uses for vacuum deposition comes in the form of packaging products. Vacuum coating is typically applied in polymer films with food packaging items to reduce the amount of water vapor transmission. Most of the time, you’ll notice that aluminum is the primary byproduct of the coating on polymer films. Also, multiple coating layers are used due to the sensitivity of food products.

The Bottom Line

All around you, vacuum deposition systems are being used to treat the items that you use on a daily basis. Furthermore, it should also be noted that these items undergo a lengthy process to achieve the gorgeous aesthetic appeal that they currently have. Vacuum deposition has been around for a long time, and throughout the years, the process has improved profoundly. It’s only a matter of time before it breaks boundaries and reaches new heights.

Denton Vacuum, LLC is a leading manufacturer of deposition products. If you are looking for quality and durable sputter coater, visit Denton Vacuum, LLC online today.